Dissolved Air Flotation Innovation

Our Flagship Product – The DAF….

11 years of R&D to date has made our Dissolved Air Flotation units (DAF) a flagship product within the Wastewater Treatment industry.

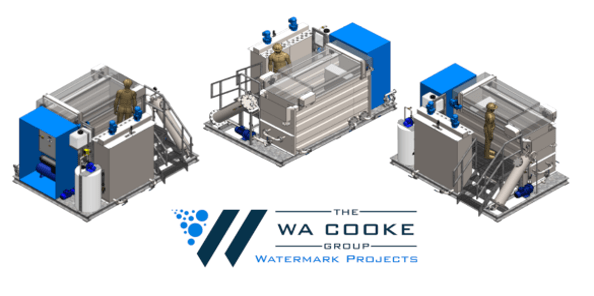

In addition to our bespoke DAF systems which reach up to 200,000 litres of wastewater per hour, we also offer 3 skid mounted variations; starting with the Model 6, then up to the Model 10 and finally the Model 20, our largest unit with the ability to process up to 40,000 litres of wastewater per hour.

All 3 DAF products are developed, manufactured and shipped from our bases in Manchester and Ely, Cambridgeshire.

Our DAF models offer an effective and reliable solution to any and all sized businesses seeking to clarify their wastewater in anything from food processing to plastic recycling.

Overcoming Obstacles….

Despite the success of our DAF units in the last 11 years, it wasn’t all smooth sailing.

We encountered an issue with the footprint and transportation of the unit itself, due to the initial floor mounted design requiring interconnecting wiring and pipework to be completed on site resulting in significantly increased costs.

To combat this, we began developing a solution consulting all W A Cooke divisions on how to tackle the problem. The resulting solution was the development of a Skid mounted range.

While a Skid mount is a common component in engineering, our unique development was creating a layout for the DAF components (DAF Cell, Mixing Tanks, WhiteWater System, Control Panel etc.) which could work effectively on a compact skid base.

The Skid acts as a steel support structure that runs along the base of the DAF, allowing for efficient transportation, easier installation and 360-degree access making the Skid mounted range a ‘plug and play’ style system.

Now, over 90% of all of our DAF installations are from our Skid mounted range due to their reduced footprint, reduced installation costs and ease of operation.