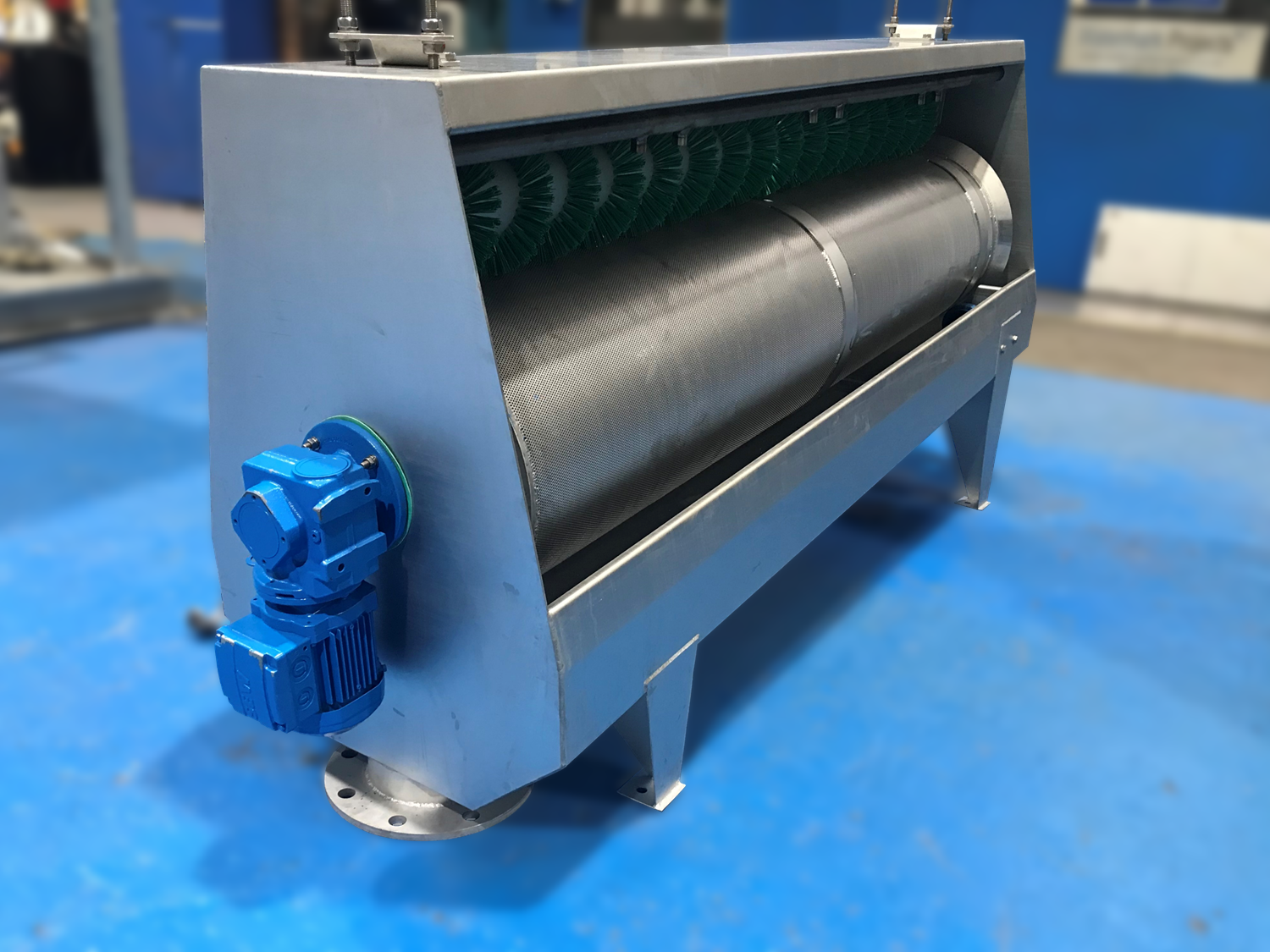

THE MIDI

The MIDI rotary drum screen aims to process up to 35,000 litres per hour of wastewater. However this figure can vary dependent on what kind of effluent requires treating. For example, if the effluent contains high levels of solids this capacity will decrease due to the density of the wastewater.

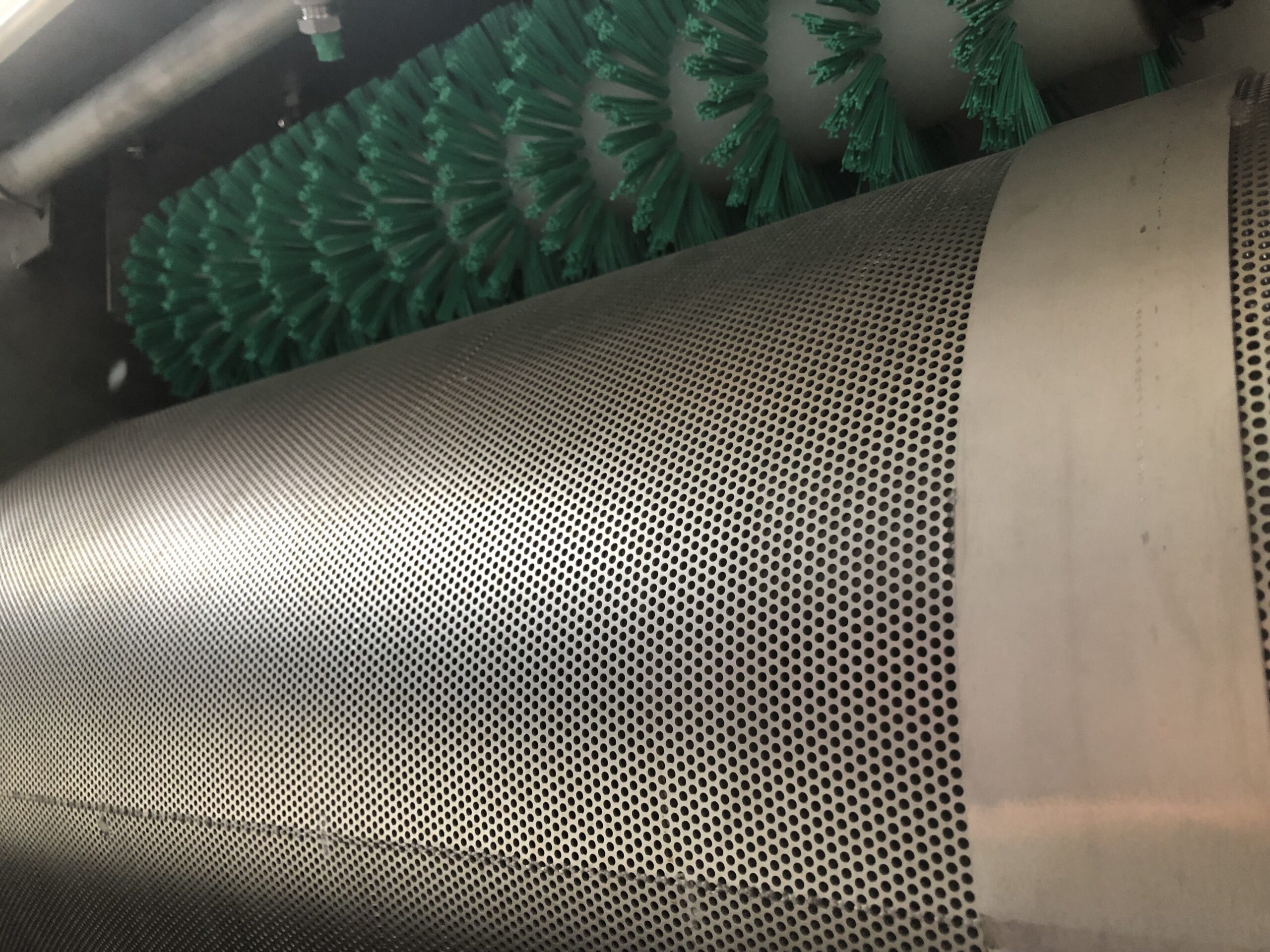

The screen itself is formed from 35 stainless steel, laser cut parts. From the mesh to the door It is built to endure what you throw at it.

If you require any further information or wish to get in touch regarding any of our products please contact us.

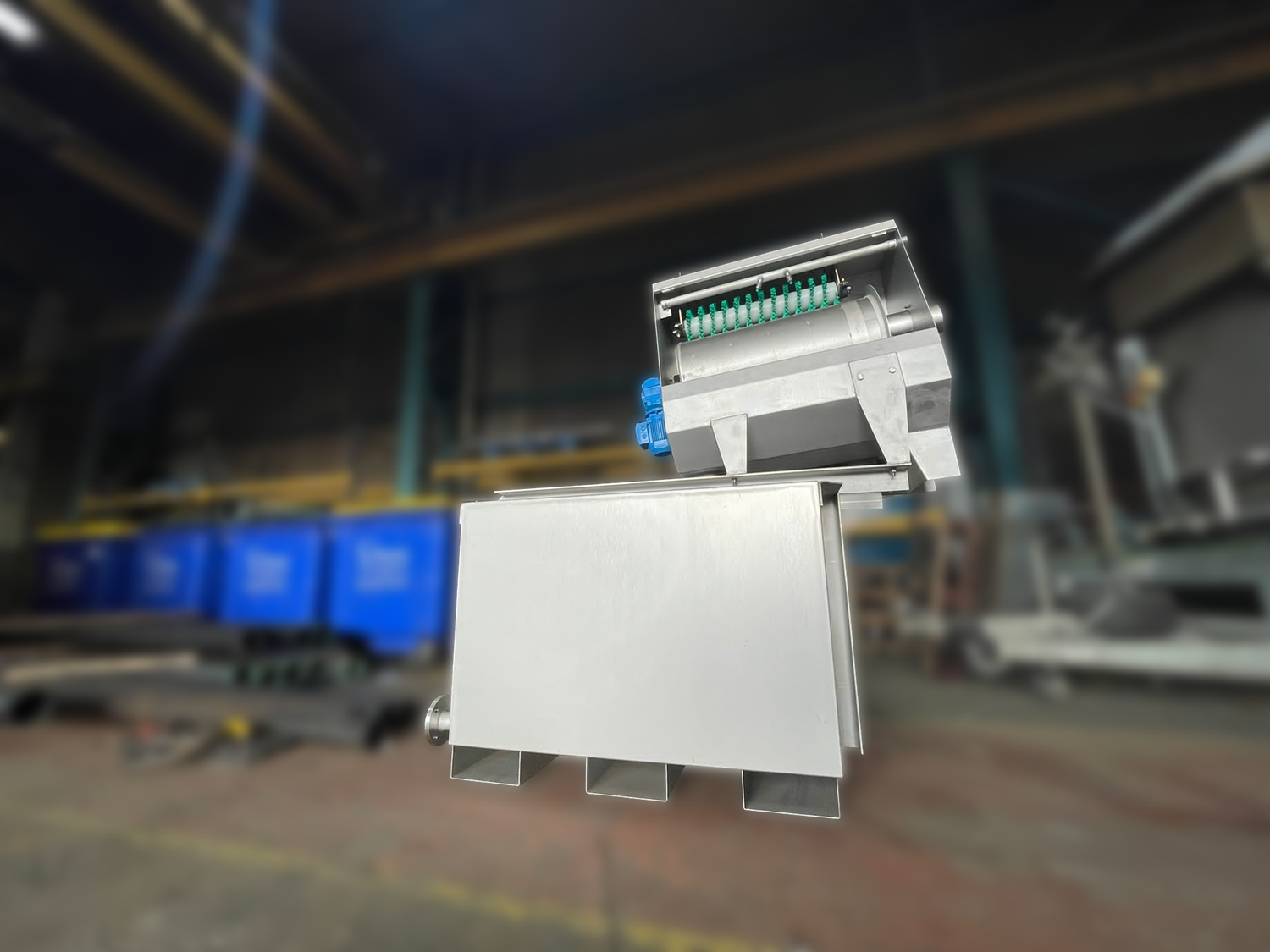

THE MAXI

Built as the step up from the MIDI, our MAXI rotary drum screen has double the capacity. Built to process up to 65,000 litres per hour, our MAXI can offer major gross solids removal. Again, the flow rate relies on what type of effluent is passing through the screen. The flow rates my vary depending on this factor.

Similar to our MIDI screen, the rotary components and the base tank itself are fabricated from stainless steel.

If you require any further information or wish to get in touch regarding any of our products please contact us.

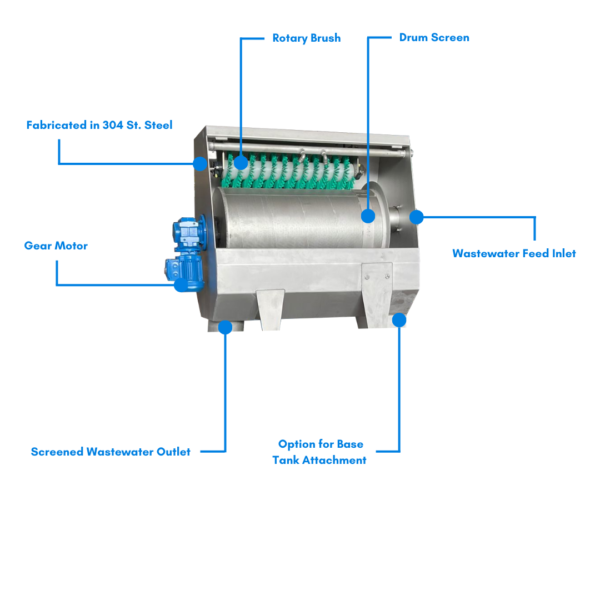

HOW DOES IT WORK?

Our two Pre Screen options: the MIDI which aims to process 35,000 litres per hour and the MAXI which can process up to 65,000 litres per hour.

The Watermark Projects pre screens are designed and fabricated to filter out Gross Solids and overall sediment within your effluent.

Simply put, The wastewater enters through a wastewater feed into the rotary screen. The water will then pass through the screen filtering out solids. The filtered water will then enter into the drum where it is pumped out onto further treatment systems where necessary.

Both of our Pre Screens have the option for base tank or high level options. Please contact us for more information.

Our MIDI and MAXI pre screens are assembled and tested in-house by our engineers. We aim to get your screen going as soon as it is installed.

Take a look what our engineers can do: