About

The size and specification of wastewater treatment system you need is generally determined by the hourly flow rate (to ensure the system can cope with the throughout) and the loading (of Suspended Solids, Fats, Oils & Greases etc.).

For example; if your wastewater has a high loading then it may be recommended that you utilise a larger capacity system to ensure effective treatment can be achieved.

Up to 10,000 litres per hour is considered a low to average flow rate, particularly in industries such as food processing where a portion of the clean water brought into site is used in the production process.

For flow rates of up to 10,000 litres per hour, we would recommend the following treatment systems:

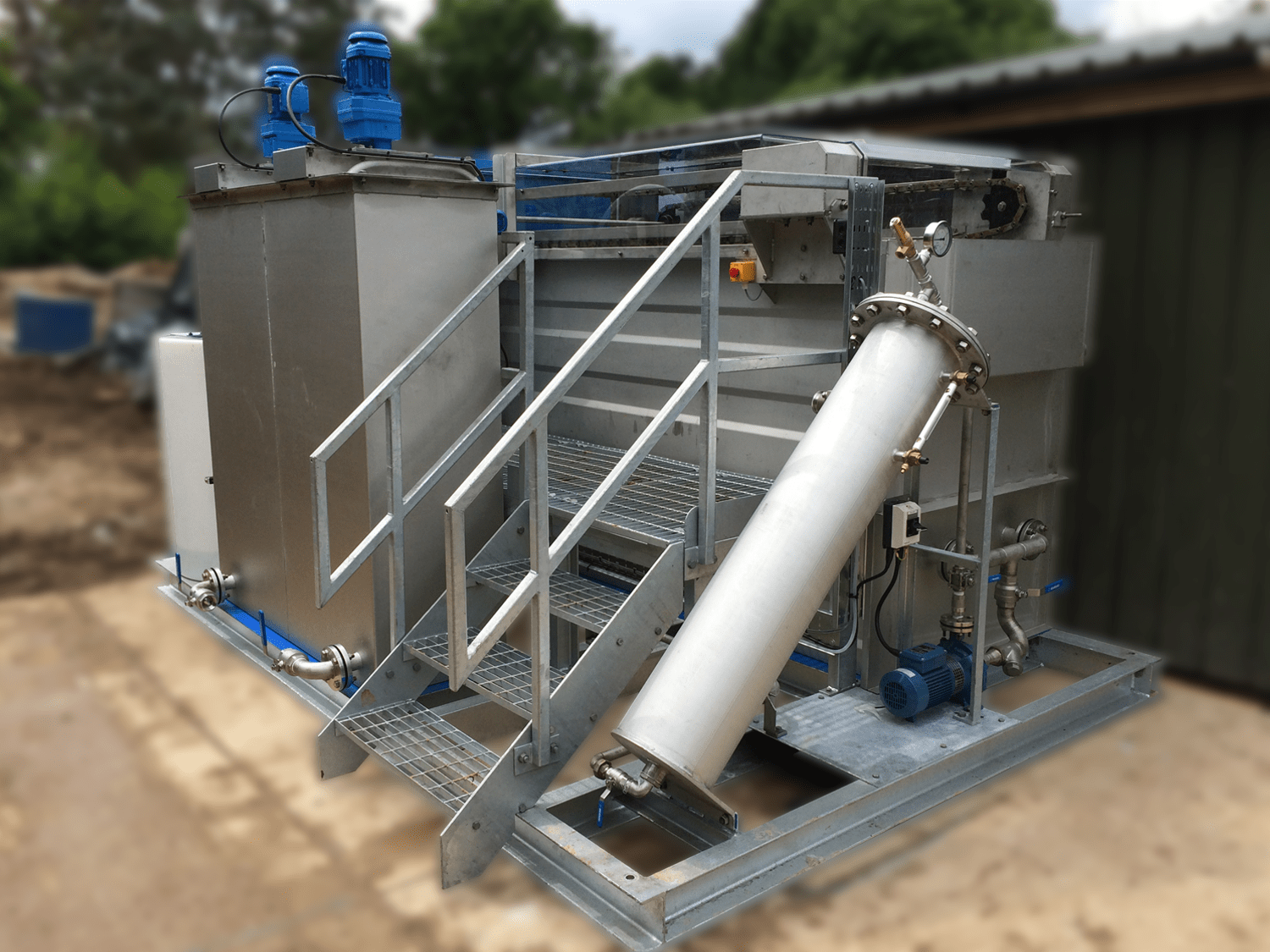

DAF Model 6

The DAF Model 6 is capable of handling up to 10,000 litres per hour utilising dissolved air flotation technology. The achievable level of flow rate will vary depending on the effluent being treated, For example an effluent with a high level of Fats, Oils & Greases will slow water flow due to its higher density.

Additionally, if less than 10,000 litres per hour is required for your treatment, then the Model 6 will cover you with room for future effluent increase where necessary.

To future proof your wastewater treatment, we would suggest an upgrade to our Model 10 which can handle a higher level of loading.

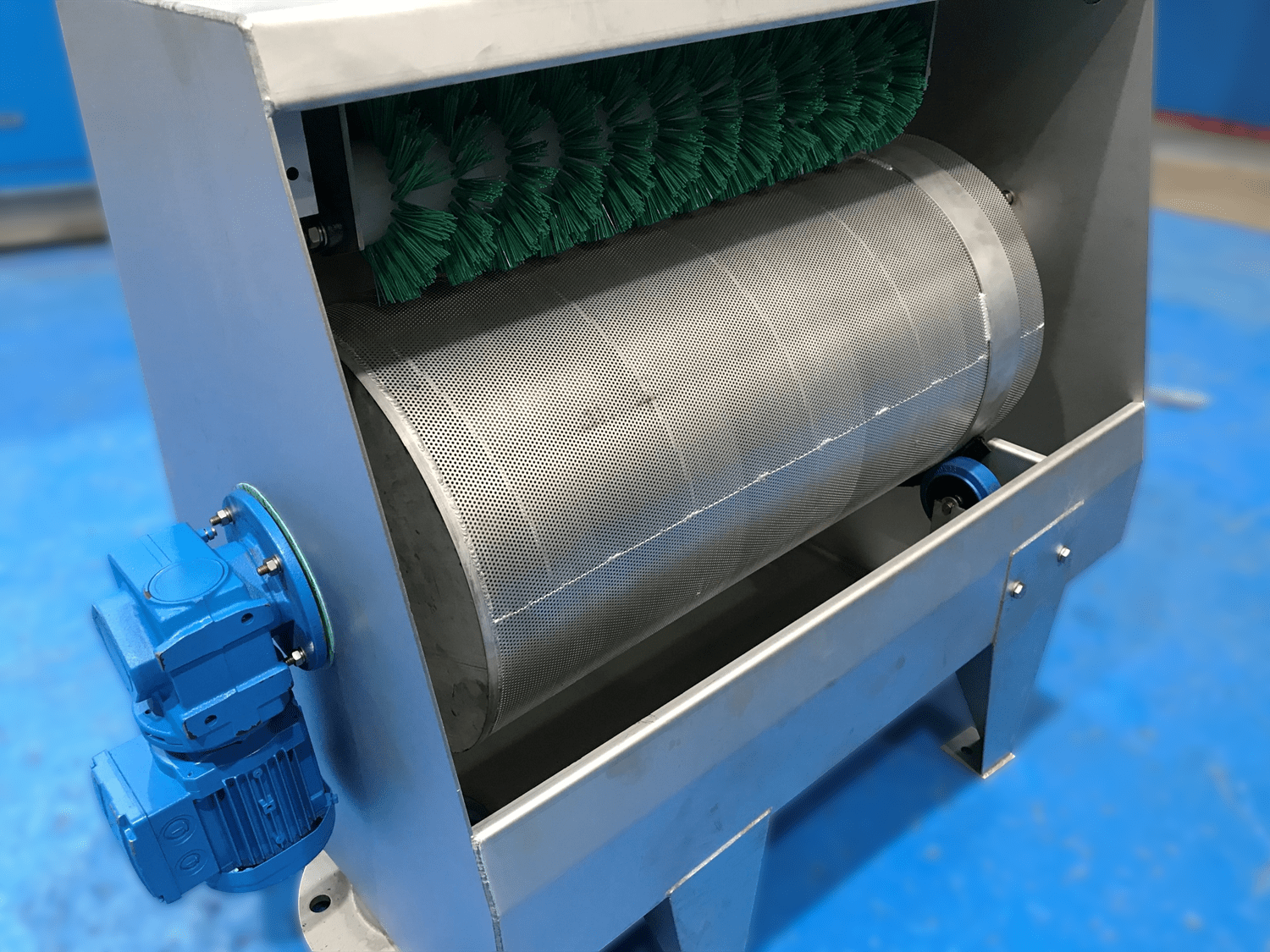

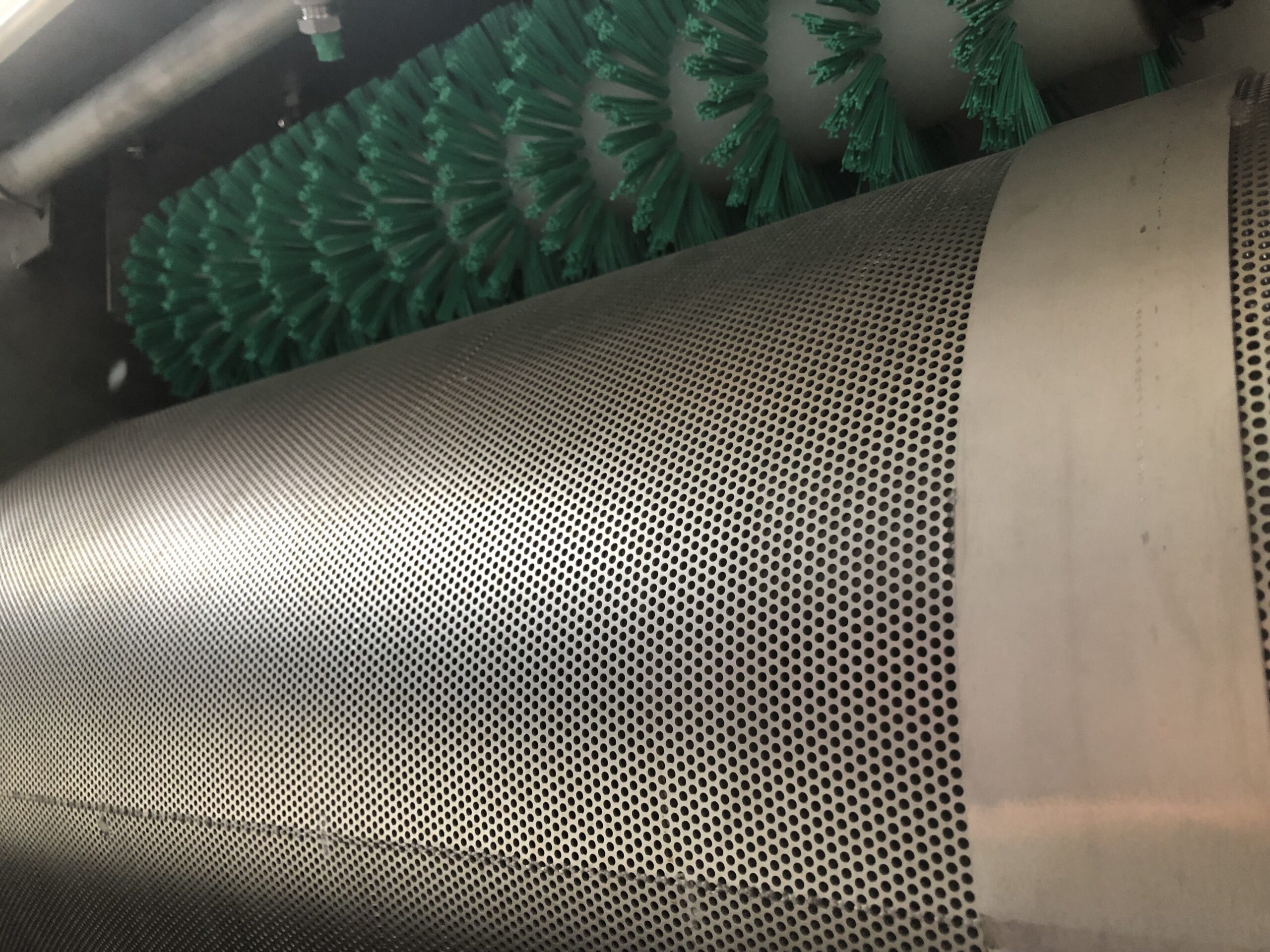

Pre-Screen MIDI

Watermark Projects Pre-Screen MIDI is the smaller of two rotary screening products we offer. The MIDI has a capacity of between 15,000 and 30,000 litres per hour, offering a full gross / large solids filtration system whereby sediment is filtered apart from your waterflow. The flow rate capacity will vary depending on the effluent it is treating. For example an FOG heavy effluent will likely have a lower capacity than an effluent with a high level of TSS.

Our rotary screens come with the option for a mounted steel base tank, or a high level mount placed on either a balance tank or platform with access steel.

The Pre-Screen MIDI is the answer to any stage one water treatment procedure required.

De-Watering SP2000

The SP2000 Dewatering Screw Press. Skid mounted and available with or without onboard polymer dosing.

If you’re unsure of your flow rate you can check your recent bills from your local water authority to see how much you are discharging per month. You can then determine your average flow rate by dividing this by your monthly operating hours but this will not highlight any peak flows which could impact the size of treatment system you require.