Pre-Screening offers an affordable and reliable solution to primary water treatment, Watermark Projects has its own range of in-house fabricated stainless steel rotary pre-screening to help clarify your effluent.

A high level of gross solids in your wastewater system can cause blockages and site disruption. When a high amount of gross solids is left untreated, the accumulated sediment will require manual removal.

This is where our screens come in...

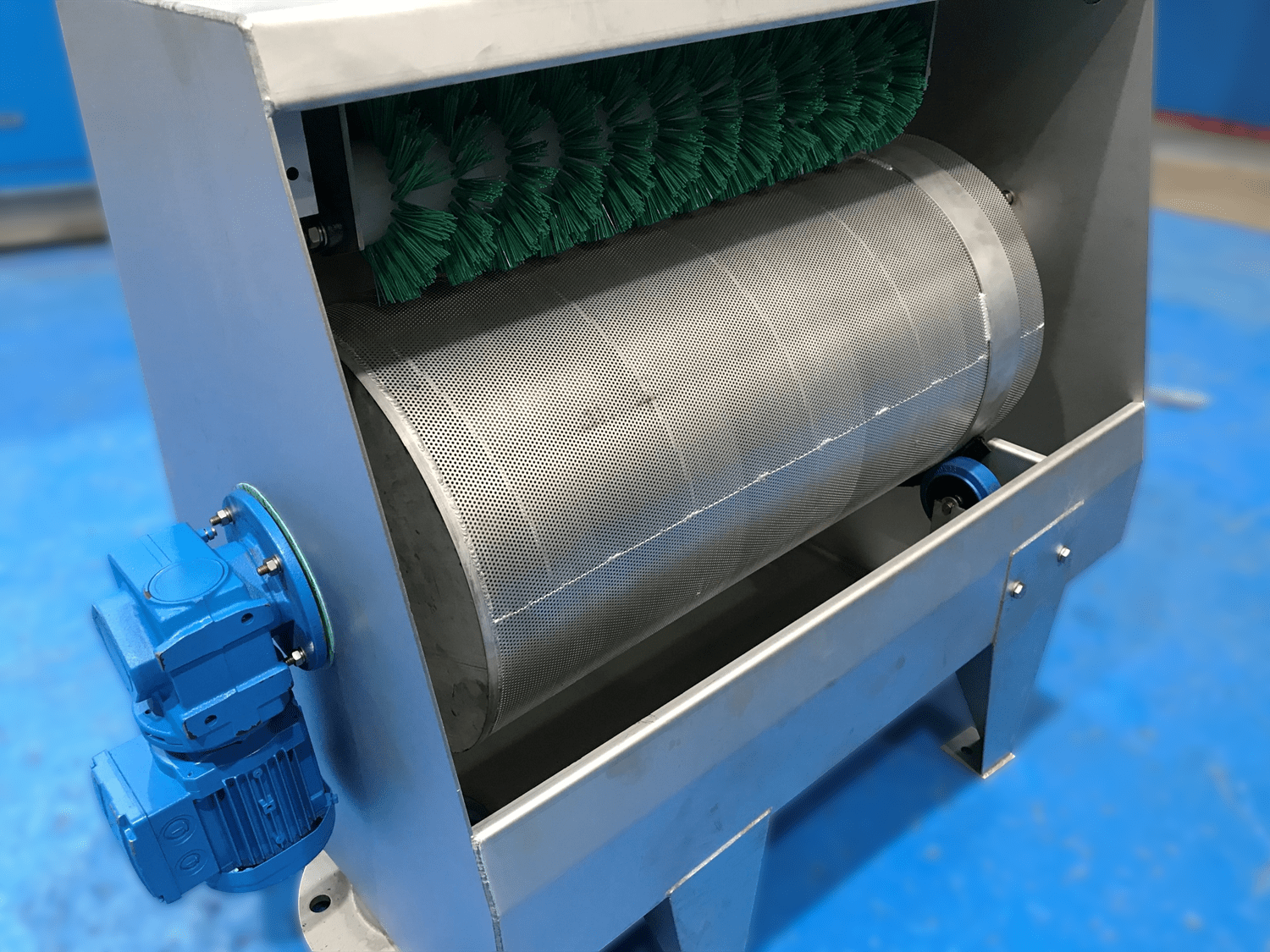

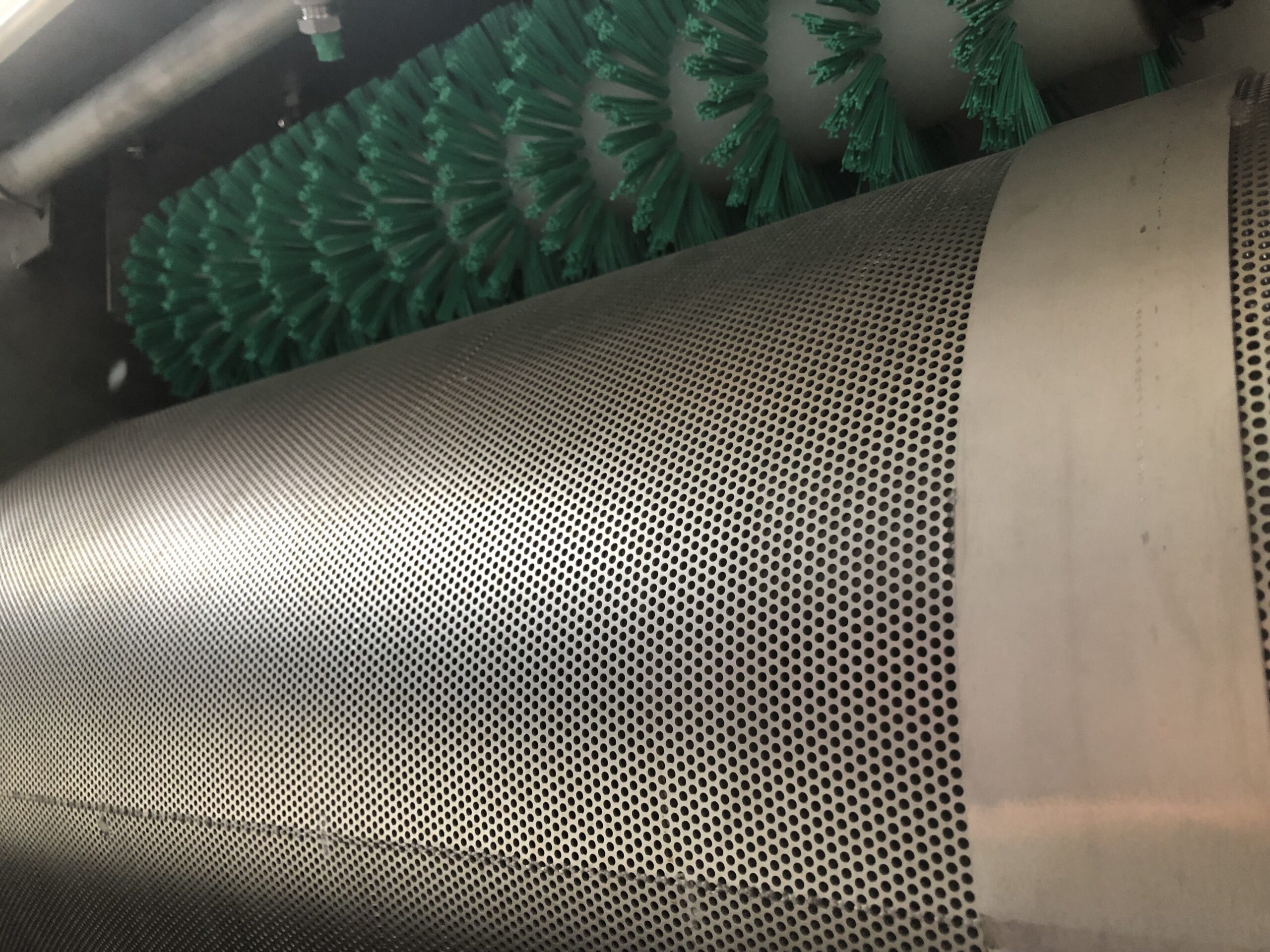

The first line of defence against gross solids. Able to filter out sediment through a rotary mesh screen, our pre-screening systems can separate contaminants from your effluent water, helping to reduce site disruption and avoid high fines from wastewater regulators.

OUR PRE-SCREENING PRODUCTS:

MIDI

Pre-Screen Unit

MAXI

Pre-Screen Unit

- Can load up to 35,000 litres per hour

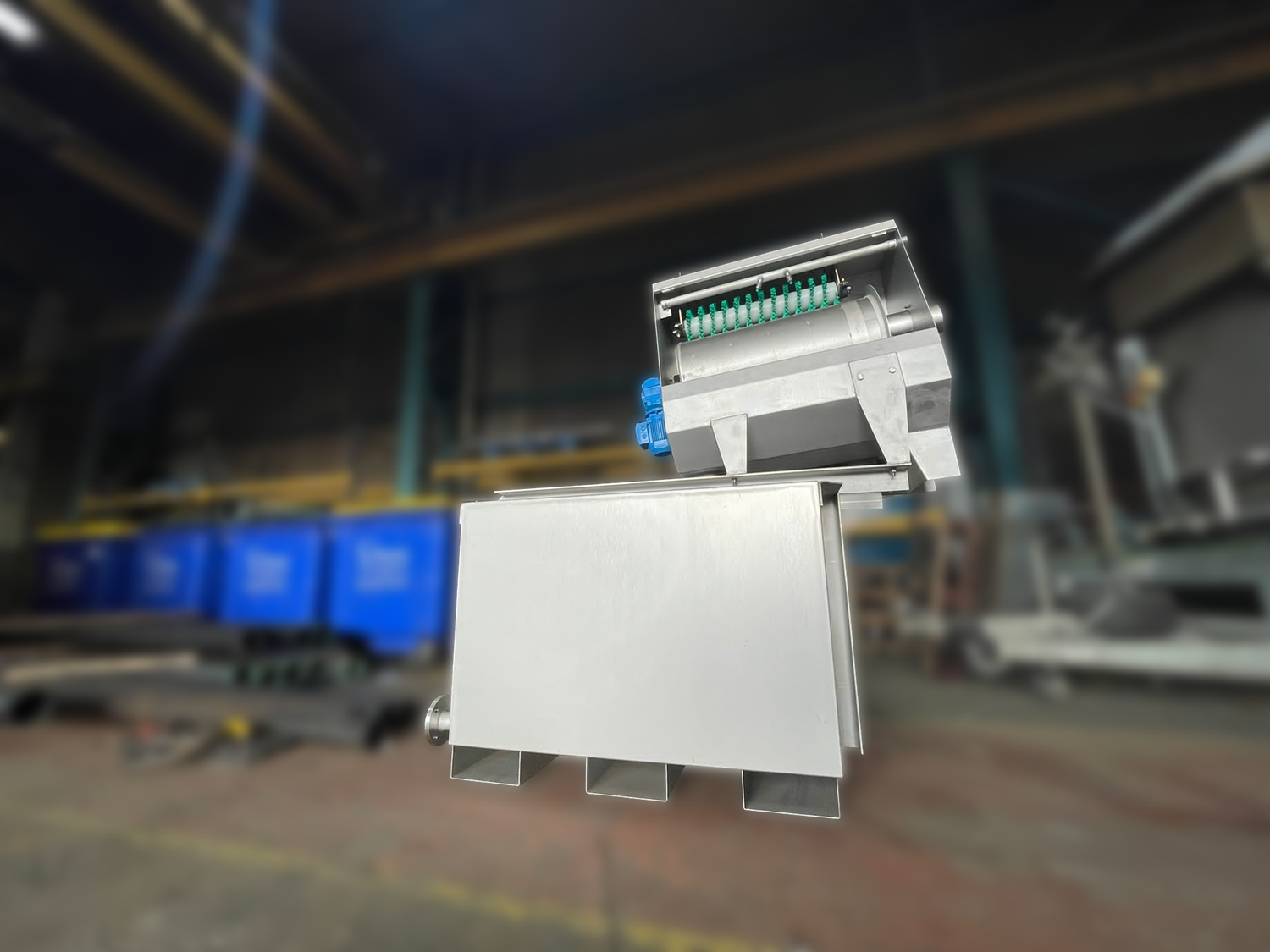

- Option for base tank or high level mount

- Can load up to 65,000 litres per hour

- Option for base tank or high level mount

- All of our pre screens have high and low level options tailored to your needs. This opens up the option for an attached base tank.

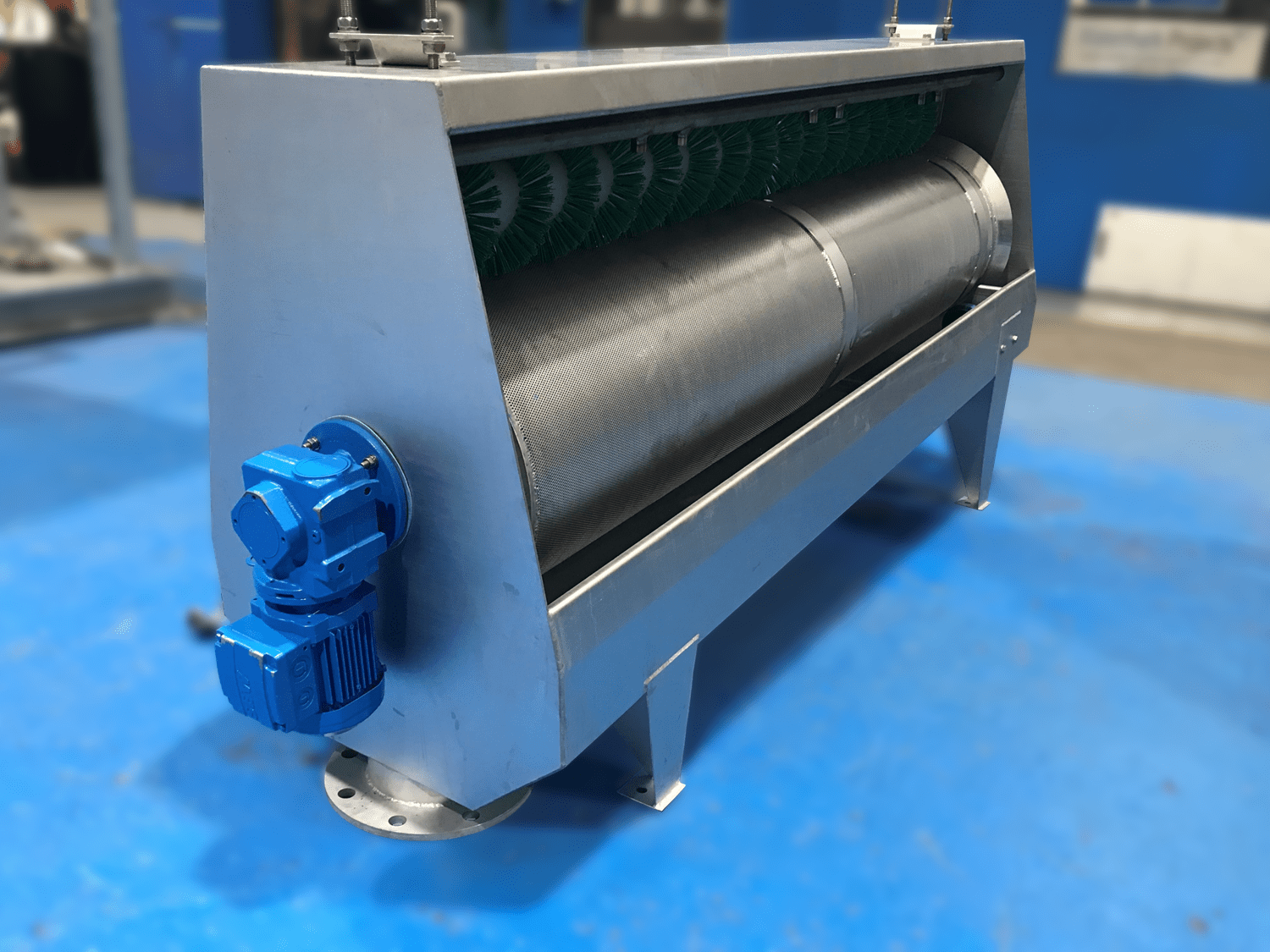

- The screens themselves are fabricated out of 304 stainless steel for added endurance.

HOW DOES THE PRE-SCREENING PROCESS WORK?

Our rotary drum pre-screens aim to remove solids from effluent water. This process begins when the wastewater enters the horizontal cylinder where the durable mesh screen is found. This screen is in effect, a cylindrical drum screen that can rotate at varied speeds, filtering solids at a controlled rate.

Solids filtered out by the screen will enter a separate outlet leading into a sediment collection point. The clarified water will then carry on through the tank, and is pumped out into further treatment systems where necessary.

An excellent addition to any wastewater treatment plant, our rotary drum screens offer instant cost reductions at an affordable price.