Skid mounted sludge de watering built to help you with your effluent treatment with the option to add onboard polymer dosing.

Our Sludge Dewatering or sludge thickening models, are high performing, sludge dewatering systems. They can help in the effluent treatment process through separating water from thickened sludge.

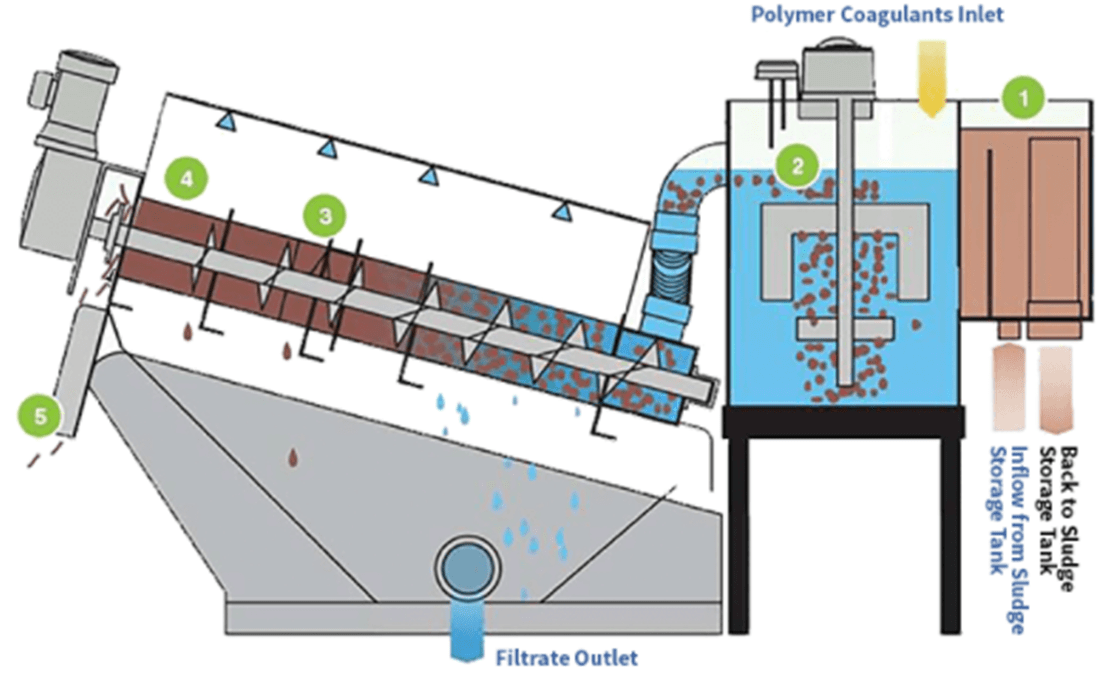

Utilising a central screw auger and a slowly oscillating multi-disk filter, the unit gradually increases pressure on flocculated sludge. This produces an exceptionally dry sludge cake. With electrical, water and the option for polymer usage, these models benefit from high capture at a cost effective rate.

OUR SKID MOUNTED SLUDGE DE-WATERING PRODUCTS:

SP2000

Sludge De-Watering Unit

SP4000

Sludge De-Watering Unit

- Up to 14kg/h de-sludge capacity

- 2000 x 785 mm sq.

- Up to 70kg/h de-sludge capacity

- 3330 x 1005 mm sq.

- What sets these wastewater treatment systems apart is the ability to add one of our skid mounts. Essential for easier transportation, installation, and minimising the overall site disruption. This applies not only to the initial installation, but also gives you the flexibility to manoeuvre this unit around your wastewater treatment plant or system.

- Additionally, you can also chose to add an onboard polymer makeup system to further treat your wastewater to the highest degree of efficiency.

HOW DOES THE DEWATERING / SLUDGE THICKENING PROCESS WORK?