OUR SKID MOUNTED DAF PRODUCTS:

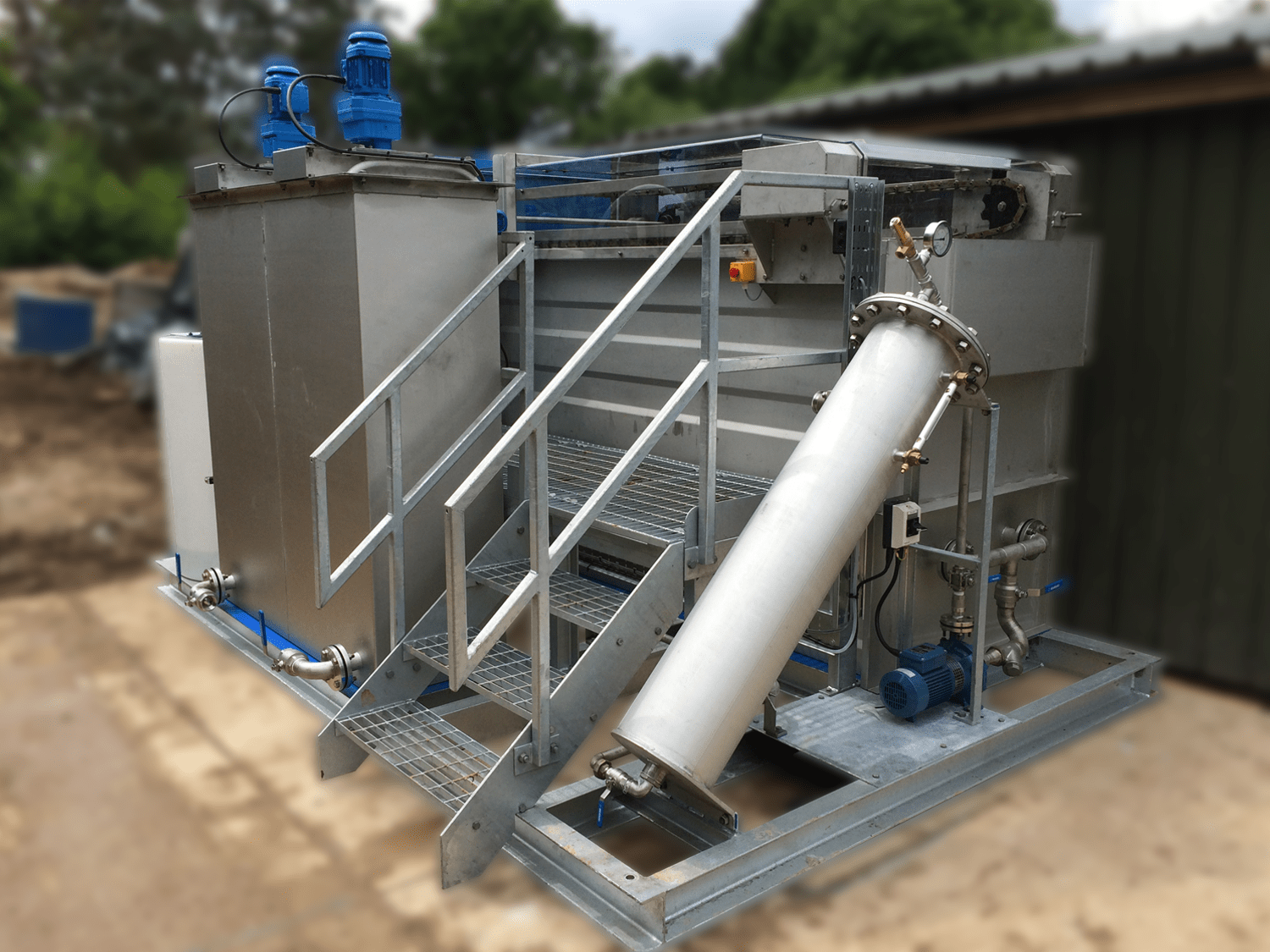

The DAF Model 6

Dissolved Air Flotation Unit

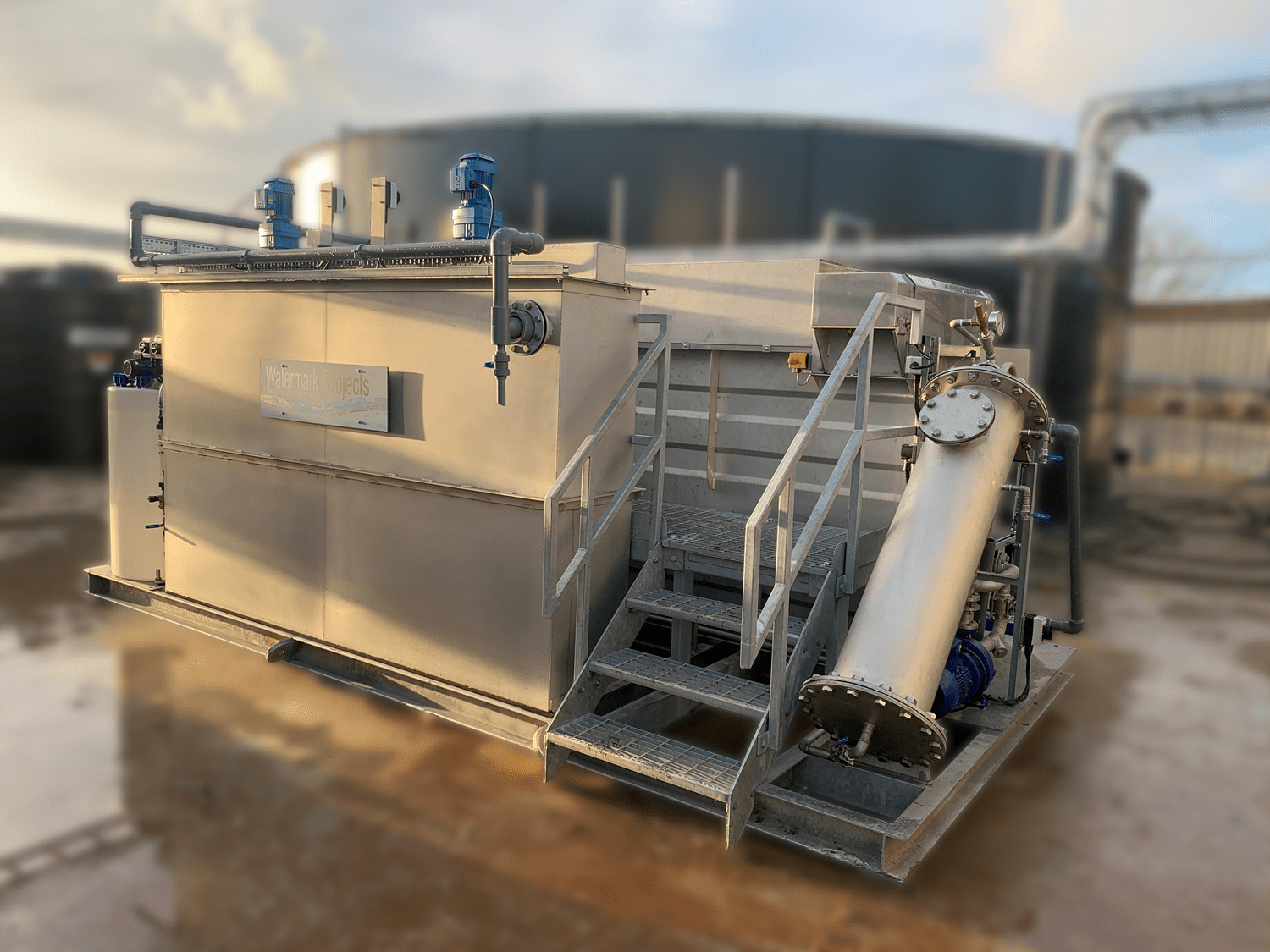

The DAF Model 10

Dissolved Air Flotation Unit

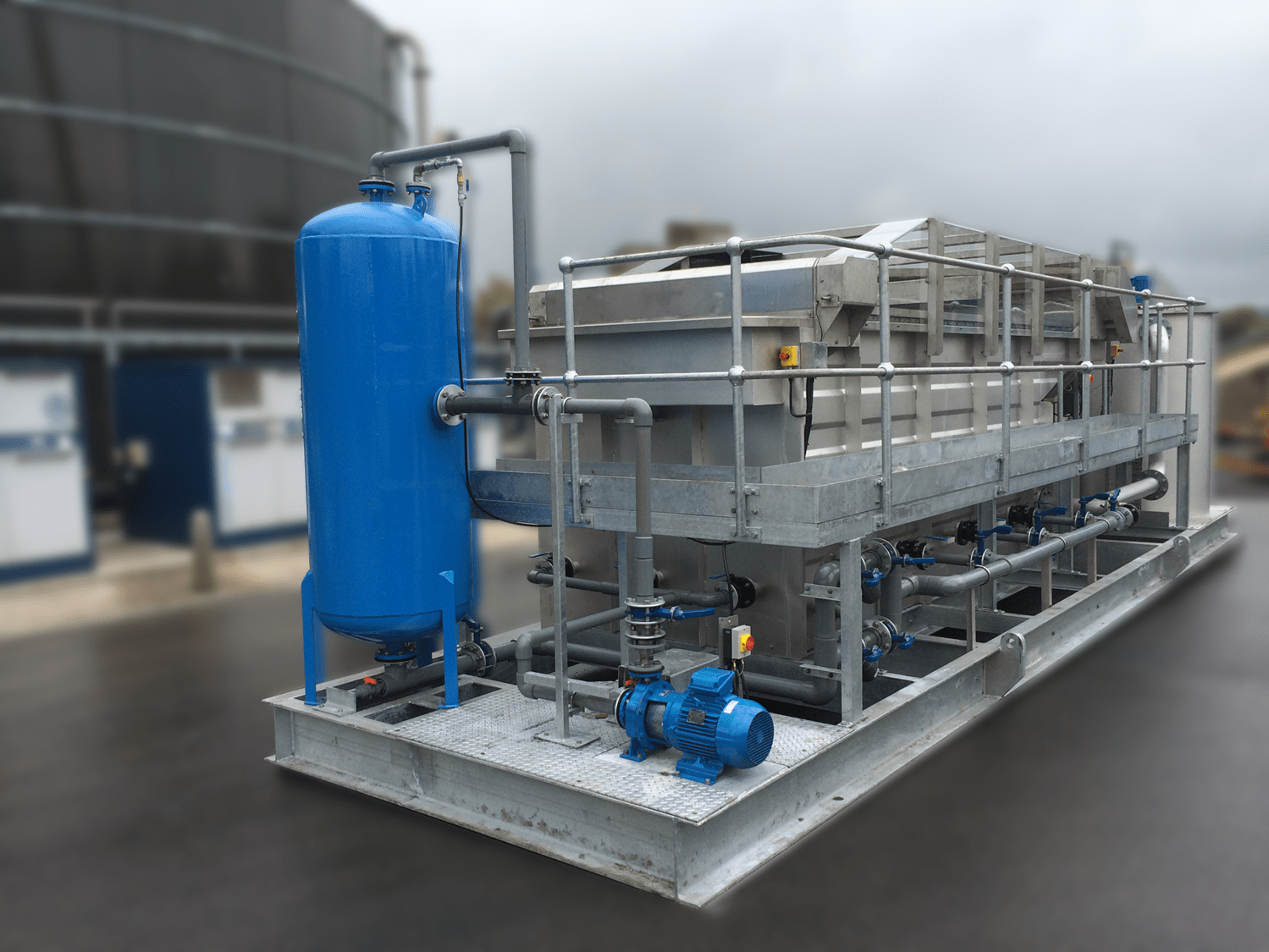

The DAF Model 20

Dissolved Air Flotation Unit

- Up to 9,000 litres per hour

- 4,000 x 2560 mm sq.

- Up to 20,000 litres per hour

- 5,380 x 2560 mm sq.

- Up to 40,000 litres per hour

- 10,000 x 2560 mm sq.

Watermark Projects also offers pH Correction and Chemical Treatment services.

The Watermark Projects DAF systems are designed to offer a complete wastewater treatment solution with on board chemical mixing vessels, dilute polymer make-up system, complete PLC control panel, pH control and level controllers for automatic operation.

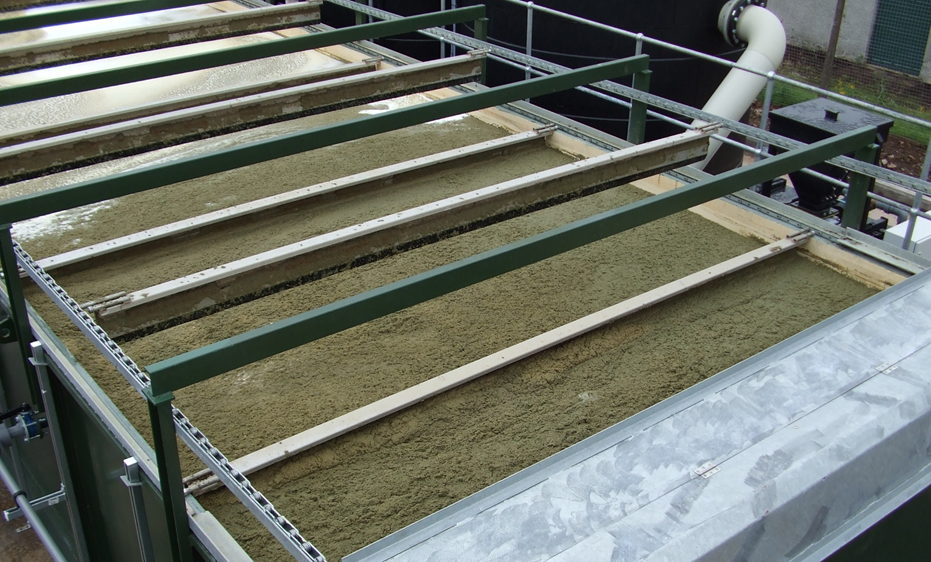

Shown below are our skid mounted DAF range. These units range from 3,000 to 40,000 litres per hour. The skid mounted design allows our DAF systems to be fabricated, delivered and installed more efficiently as they are effectively one piece.

All of our DAF systems offer a reduction rate of up to:

COD Removal

Chemical Oxygen Demand

TSS Removal

Total Suspended Solids

FOG Removal

Fats, Oils & Greases

- Alternatively, if you require more than 40,000 litres per hour of wastewater treatment, our off skid / Bespoke range will address larger quantities of effluent from (but not limited to) 40,000 to 200,000 litres per hour.

- Watermark Projects can offer a trial DAF to see what our DAF systems can offer you before purchasing. Additionally, you can rent a DAF if you are looking for a more flexible option.

HOW DOES THE DISSOLVED AIR FLOTATION PROCESS WORK?

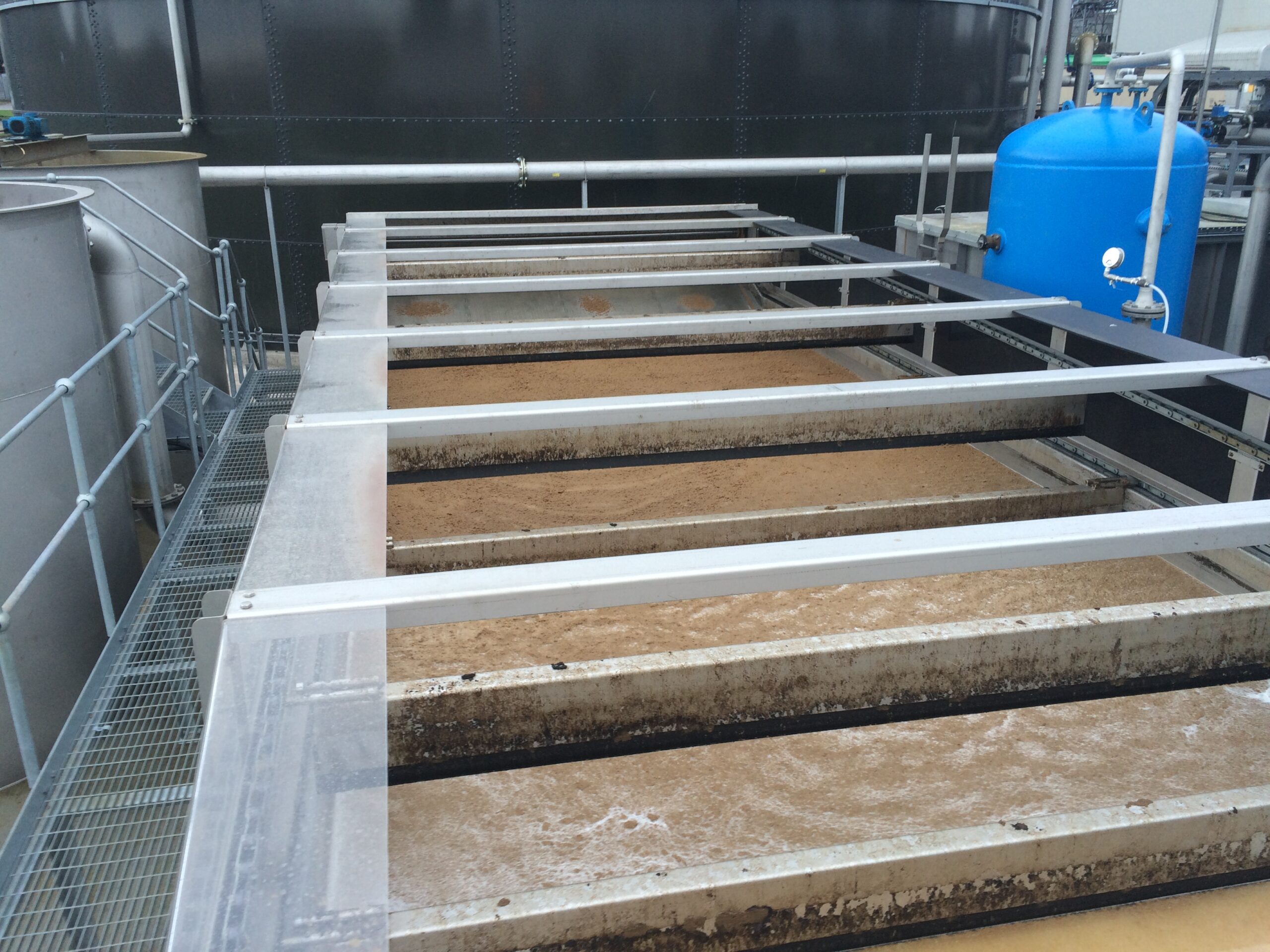

The Dissolved Air Flotation or DAF treatment process is designed for the efficient removal of COD, suspended solids and fats, oils and greases from the effluent stream. The system utilises fine air bubbles, also known as ‘White Water’, which attach themselves to the suspended material within the waste stream, increasing buoyancy and floating them to the surface. The floated solids are then removed by a simple but effective scraper mechanism. More often than not chemical conditioning is used to increase the effectiveness of the Dissolved Air Flotation process.

The Watermark Dissolved Air Flotation process uses the most reliable and positive method of producing air bubbles of the optimum size. This is done by dissolving air into water under pressure and then dropping the pressure on entry to the DAF cell using a controlled nozzle orifice. As the pressure is reduced, the air naturally comes out of solution in the form of micro bubbles.