HOW DOES IT WORK?

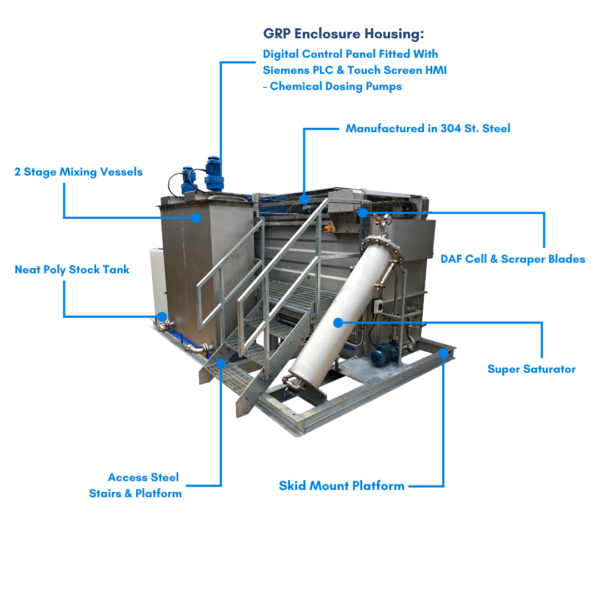

Manufactured with the purpose to reduce and remove COD, TSS and FOG from wastewater, the Watermark Projects DAF Model 6 unit is a compact, skid mounted complete treatment system capable of treating up to 10,000 Litres per hour.

Like all of our Dissolved Air Flotation systems, the DAF Model 6 utilises level sensors or float switches to automate the wastewater treatment process.

Once the pre-set sensor signals the feed pump, the system draws effluent directly into the on-board mixing vessels. This is where chemical treatment, pH correction and flocculation occurs. The treated effluent then passes into the Dissolved Air Flotation cell where the automated air dissolving vessel (our own robust super saturator unit) introduces highly air saturated water. The saturated water floats the flocculated waste to the surface for removal by a chain driven scraper blade.

To ensure the remaining water is free from solids, it is fed under a baffle and then over a weir plate for final discharge or even further treatment.

TECHNICAL INFORMATION

The DAF Model 6 system offers the same robust structure as our other models and bespoke systems. However, adopts a new layout which allows us to optimise every inch of ground space required on site.

- Treats up to 10,000 litres per hour

- 4,000 x 2650 (mm sq.)

- 2524 h. (mm sq.)

- Digital control panel

- Skid mounted

- Fabricated in 304 stainless steel

- 2 m2 DAF cell (T304 stainless steel)

- 2 stage variable mixing vessels

- Automatic dilute polymer makeup system

- pH controller

- pH adjustment dosing pump

- Coagulant dosing pump

- Sludge transfer pump

- 1.1 KW integral air compressor

- Digital control panel fitted with a Siemens PLC & touch screen HMI

- Lockable GRP enclosure (housing control panel)

- Integrated skid & access platform

- 2 scraper blades

- Inverter driven, self-priming, positive displacement feed pump

DELIVERY, INSTALLATION & COMISSIONING

All of our DAF systems are installed & commissioned by our in-house engineering team.

Thanks to its skid mounted design, the Model 6 is able to be installed & commissioned with minimal site time. With interconnecting pipework & all ancillary instrumentation (such as pumps, compressor, control panel etc.) pre-installed and tested on the skid base. The unit offers as close to Plug & Play setup as possible.

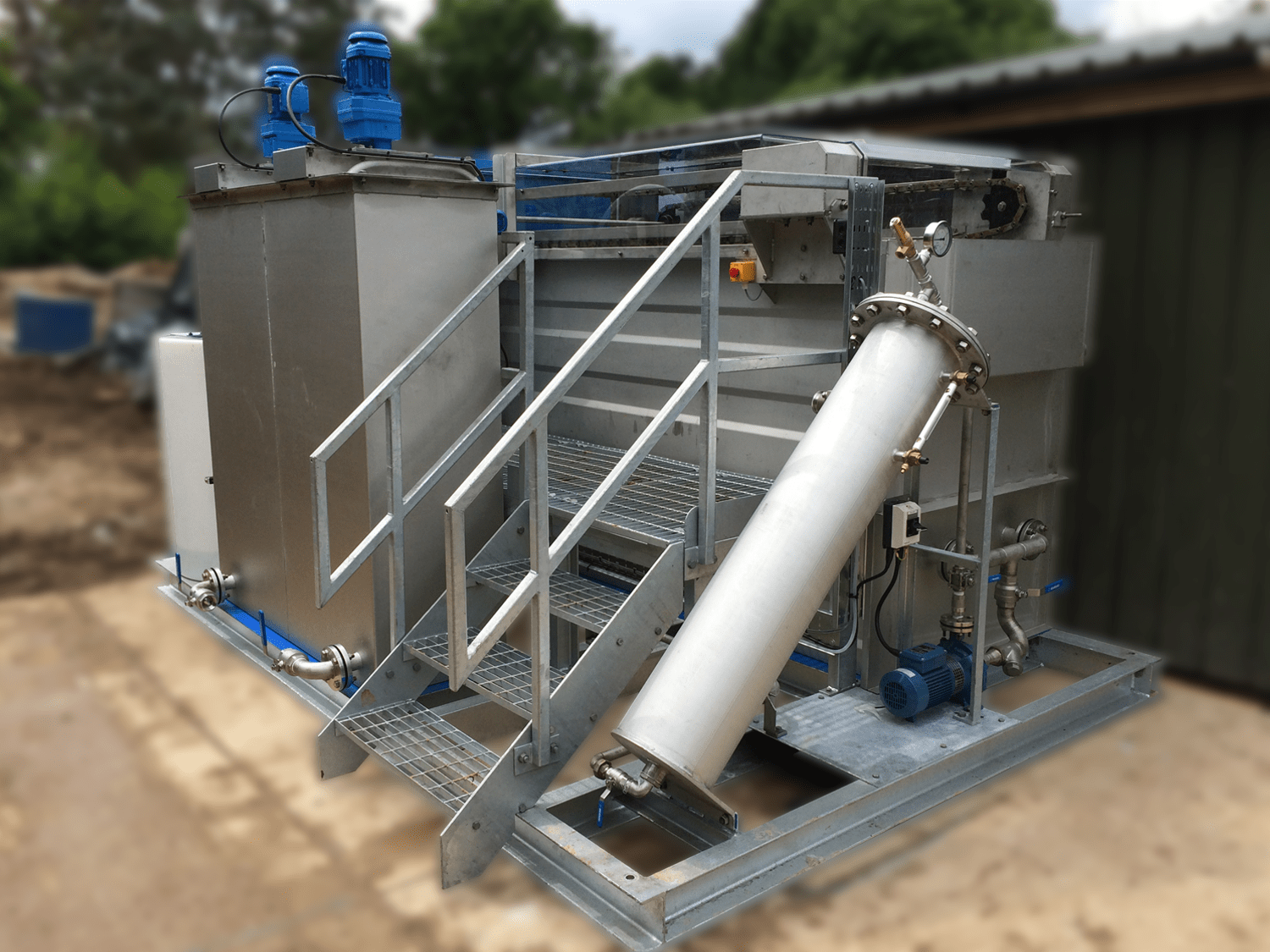

Take a look at this recent installation we fulfilled for one of our clients:

Scheduled Servicing Now Available

To view our Platinum, Gold, Silver and Bronze servicing package options, click here: